Key Market Advancement

Manufacturing is a key industry of global economic development. Similar to an iceberg, the finished product represents just a small fraction of the entire process. There are other to-do items that happen behind the scenes that support production.

As the lead UX designer, I developed and refined a proof of concept aimed at optimizing task management for non-production activities.

I also proposed complementary solutions that support the client in achieving their process improvement objectives and expansion goals. The solutions included here provide them a key market advantage over competitors in an emerging market.

Additionally, I explored ways to leverage AI to enhance task coordination while promoting team ownership, visibility, and empowerment.

Tasks

User Research, UI/UX Design, Usability Testing, Prototyping

Skills

Wireframing, Figma, Miro, AI

Time Constraint

3 Months

Industry

Manufacturing, Technology

Final Solutions

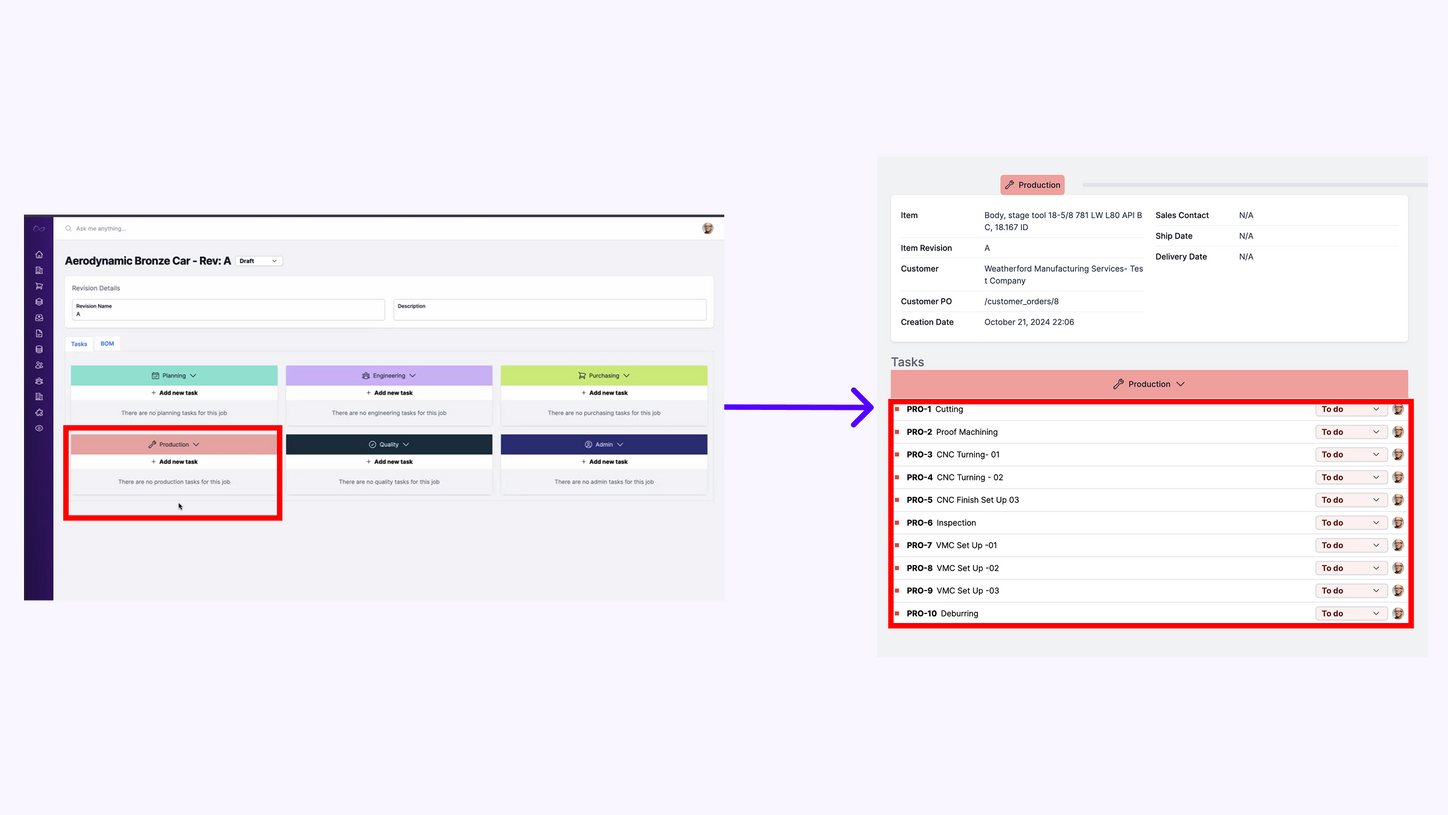

A Single Source of Truth

Established a centralized hub to monitor the progress of all manufacturing jobs. This tool enables the ability to track advancements across every manufacturing process effectively, benefiting the organization, teams, and individuals. Now, there is visibility into the tasks assigned to each team member and individual.

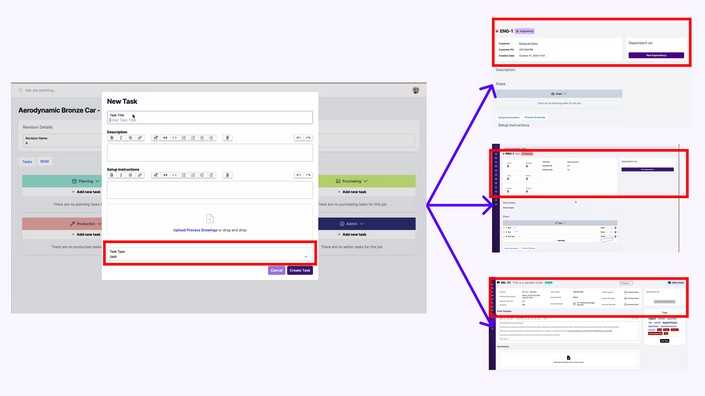

Easy Task Creation and Management

Every department is responsible for managing its own to-do items that are essential for each client assignment. Each task represents the smallest unit of work necessary for a particular team to complete its responsibilities. Additionally, each team or "stream" has the autonomy to create templates that can best suit their needs.

What else was created?

Results & Impact

-

This project demonstrated that it is possible to effectively track progress across all manufacturing process activities in a way that supports the organization, teams, and individuals.

-

A demo system based on a project, which received 95% positive feedback during a limited factory release. This solution addressed a long-standing issue and aligned with the client’s goals for team maturity and organizational expansion.

-

There's a significant gap in user experience within large-scale manufacturing, as most products target smaller operations. This solution created for Ominitech gives them an edge over other competitors by over 45%.

-

Improved and clearer dashboards and key performance indicators (KPIs) increased visibility and transparency by a 75% margin.

-

The initial proof of concept yielded enhanced productivity in their day-to-day tasks through the integration of AI. The team is excited to continue teaching the AI model about their workflow, processes, and procedures.

Initial Context

Client Background

Omnitech Engineering Limited stands as one of the largest manufacturing companies in Gujarat, India, and has been delivering exceptional excellence and expertise for over 20 years. They have a diverse array of clients in different industries, such as oil and gas, agriculture, and aviation—just to name a few.

In the competitive landscape of an emerging manufacturing market, companies like Omnitech must consistently prove their expertise to secure contracts. Clients usually impose stringent and comprehensive requirements that machine shops must meet in order to consider their projects to be successfully completed.

Omnitech has not only met these challenges but has also excelled by executing each job with precision and unwavering attention to detail. This commitment to quality has solidified their reputation and generated an overwhelming demand for their services, which they are adept at managing despite the challenges.

Why does this project matter?

Most enterprise management software solutions for manufacturing shops tend to focus heavily on core processes, such as production, scheduling, and inventory management, often overlooking important non-manufacturing tasks. However, fulfilling job assignments effectively requires addressing these items as well.

When teams are unable to track all tasks and progress accurately, it can lead to significant stress for individuals and departments. Sifting through multiple sources of information becomes cumbersome and tedious, and this can escalate, ultimately impacting production processes.

Omnitech is anticipating rapid growth in the near future. Having a streamlined and improved process to address current gaps in task management will support their expansion goals. This enhancement would enable them to focus on more critical activities essential for their success.

Problem Statement

This project aims to validate the concept of establishing a single source of truth for all manufacturing tasks. This solution enables users and teams to perform their assigned work efficiently and collaborate effectively. It allows leaders to access real-time data, ultimately enhancing productivity and effectiveness across the organization through the use of AI.

Initial Discovery

My prior experience in manufacturing focused on small to medium-sized businesses, where a few individuals commonly performed multiple roles in the production process. In contrast, Omnitech operates in an emerging manufacturing market that allows for rapid growth, specialization, and an overall larger operation.

My initial assumption was that, as a larger organization, Omnitech would have a defined structure that assigns ownership of different sections of the manufacturing process. After assessing their processes, I confirmed my theory when I discovered they have a well-established organizational chart where different departments own a portion of the overall manufacturing process.

Each department and user role already understand their roles, duties, and responsibilities well. However, simpler user workflows and better visibility were needed for their own work and that of other departments.

In an effort to get an even deeper understanding of Omnitech’s work, I was invited to go visit their factory in Rajkot, India. This trip was really useful for me because it allowed me to see first hand their operations, and get a much perspective from each team.

An Unexpected Journey

After my in-person visit, I identified several challenges:

1. There is an overall lack of clearly defined task ownership, which creates confusion among individuals and teams. People often do not know whom to contact when issues arise, whether in general or regarding specific processes.

2. People are engaging with too many sources for task tracking and progress recording. This leads to confusion, missed data, errors in their work, and disconnection within internal teams.

3. The numerous data sources hinder team collaboration and support across departments. Each team operates in a silo and lacks sufficient context about the work of others, which prevents seamless cohesion.

4. Leadership struggles to accurately measure team productivity and identify areas for improvement. Existing tools focus on measuring job outcomes in terms of financial success while neglecting key indicators of team performance and productivity.

5. Clients expect regular updates on job status, which can be difficult to manage without a clear internal tracking system. While clients deserve to receive updates, not every small task requires a notification.

After my in-person visit, I identified several challenges:

1. There is an overall lack of clearly defined task ownership, which creates confusion among individuals and teams. People often do not know whom to contact when issues arise, whether in general or regarding specific processes.

2. Employees are engaging with too many sources for task tracking and progress recording. This leads to confusion, missed data, errors in their work, and disconnection within internal teams.

3. The numerous data sources hinder team collaboration and support across departments. Each team operates in a silo and lacks sufficient context about the work of others, which prevents seamless cohesion.

4. Leadership struggles to accurately measure team productivity and identify areas for improvement. Existing tools focus on measuring job outcomes in terms of financial success while neglecting key indicators of team performance and productivity. This limitation hampers their ability to streamline operations and implement process improvements.

5. Clients expect regular updates on job status, which can be difficult to manage without a clear internal tracking system. While clients deserve to receive updates, not every small task requires a notification.

An Unexpected Journey

Ideating Solutions

Thinking Outside the Box

Any solutions developed for the company should focus on consolidating data resources into as few locations as possible to maintain data integrity and consistency.

I conducted a preliminary competitive analysis of existing manufacturing management systems to identify potential solutions. I explored various "out-of-the-box" options that might meet the client's needs, such as JobBOSS, Fulcrum, Katana, and IFS, along with other direct and indirect competitors in the manufacturing software sector.

Recognizing that improving task management is one of the primary goals of the project, I realized I needed to focus more on this area, even outside the manufacturing sector. I drew inspiration from leading products in the field, such as Jira, Asana, and Trello, to explore potential solutions for the client:

-

I envision a centralized hub that consolidates all tasks from various teams, referred to as "Streams."

-

This hub would allow everyone to view their own tasks as well as those of others.Each department would have a designated "bucket" for managing its tasks, ensuring total visibility and accountability regarding the origins of to-do items.

-

Each task would have at least one designated owner, or a group of owners, responsible for tracking progress and providing updates.

Additionally, dashboards displaying key information tailored for individuals, teams, departments, leadership, and clients, with customization to meet the specific needs of each audience, are a must.

Here is a Figjam that contains some of the discovery/ideation brainstorming boards for this project. Feel free to zoom in/out as needed to learn more about how this project came to life!

Designing Solutions

User Testing + Iterations

After the initial designs were created and went through a few iterations, the development team created a demo site that could be released to the factory in a limited form. The intent was to prove that the ideas laid out in these designs were feasible and to receive feedback from actual users.

We began user testing on the demo site with the planning team (where the process begins) and then involved the engineering team. There was an overwhelmingly positive response to being able to track all tasks in one place and having micro-interactions with other users in one place, specifically being able to see each other’s progress, notes and attachments.

After user testing, there were significant changes to the designs, along with new items that were implemented as a result of feedback:

Next Steps

-

Due to the internal success of the limited experiment, Omnitech believes that this proof of concept is solid enough to evolve it into a mature in-house management system that will serve as their single source of truth. They envision it becoming an internal platform where all job operations can be managed within.

-

I suggested developing apps that would represent specific parts of the entire system to make the future solution more user-friendly and accessible to everyone

-

Most people already use apps in their everyday lives, and this could be an opportunity to leverage that to the company's advantage and make the system more simple yet intuitive based on clear roles or department workflows.

-

Each app could be tailored to specific roles or workflows within that department, and the collection of apps would form a suite of internal applications that cover the entire system.

-

-

Integrating AI further into their workflow will accelerate Omnitech's pursuit of leaner and more efficient processes

-

After observing the powerful combination of tagging and AI, it became evident that there is potential for further AI integration in different departments and workflows.

-

It could work as a cloud-based model (similar to Siri and Alexa) that could handle basic tasks on portable devices, while a localized model on physical computers could manage more complex in-house tasks.

-

-

One of the biggest lessons from the limited user testing was the need for improved user and role permissions moving forward. More precise rules governing access should be based on roles, teams, departments, etc. Only certain individuals should be able to have edit access to certain tickets.

Contact the Wolf

I want to hear from you!!

Feel free to either drop me a note or hit the chat button anywhere on the screen. 👋🏻